What Are Man-Made Fibres?

Man-made fibres are textile materials that are chemically synthesized rather than derived from natural sources. These fibres are created through various manufacturing processes using polymers, chemicals, and other substances.

Man-made fibres have transformed the textile industry, offering a wide range of benefits and applications. These synthetic fibres, precisely engineered by humans, have transformed the way we produce and wear fabrics. Through innovative processes and advanced technologies, man-made fibres provide exceptional strength, durability, and versatility, surpassing the limitations and disadvantages of natural fibres. From polyester and nylon to rayon and acrylic, these fibres cater to diverse needs, enabling the creation of comfortable clothing, sturdy upholstery, and high-performance sportswear. With their ability to enhance natural materials, man-made fibres continue to shape the fashion and textile landscape, propelling us into a future where creativity and functionality coexist seamlessly.

Table of Contents

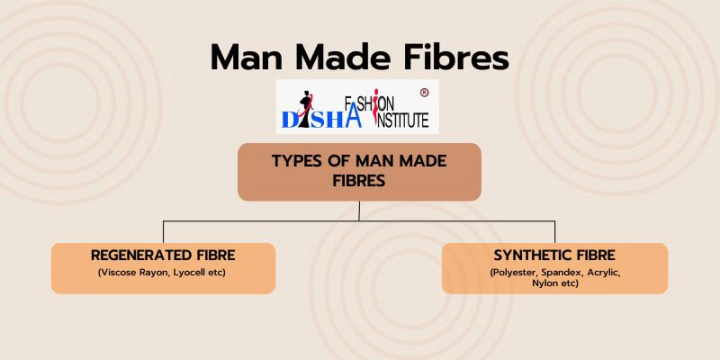

Types of Man-made Fibres

In the textile industry, we divide all types of man-made fibres into two broad categories. Regenerated fibre Synthetic fibre

Man-Made Regenerated Fibres

Regenerated fibres are basically man-made fibres prepared from natural materials, such as wood pulp or cellulose. These fibres undergo a manufacturing process to create textiles that mimic the properties of natural fibres while offering additional benefits like sustainability and eco-friendliness and making them suitable for a wide range of applications in clothing, textiles and other industries.

Viscose Rayon

Rayon is a man-made regenerated fibre, made from natural sources of regenerated cellulose, such as wood and related agricultural products. It is also known as Viscose. It is inexpensive and comfortable. The process of creating rayon involves chemically treating cellulose and then extruding it into fibres.

History of Viscose Rayon Production

The origins of rayon can be traced back to the work of French chemist and industrialist Hilaire de Chardonnet. In 1884, Chardonnet developed a method to produce an early form of rayon known as “Chardonnet silk” or “artificial silk.” But it was highly flammable and had safety risks. In the early 20th century, the viscose process was developed, which is the most common method used for producing rayon today.

Characteristics of Viscose Rayon

- Rayon is a good absorbent and can be worn in warm and humid climates.

- It is soft, feels like silk, has good lustre and is very lightweight and also good drape.

- Rayon is breathable and allows air circulation, preventing the buildup of heat and promoting comfort. It is often used in lightweight and airy garments.

- This is very stretchable sometimes causing bad shape to the garments. Low-quality rayon shrinks after washing.

- Like other natural fabrics, it is hugely used in garments, upholstery, fashion accessories etc. Besides, Rayon fibres can be found in products such as bandages, surgical gowns, disposable wipes, and feminine hygiene products.

Lyocell Fabric

Lyocell fabric, also known as Tencel, is a type of cellulose-based organic man-made fibre or regenerated fibre prepared from wood pulp. The production process involves dissolving the pulp in a solvent, spinning it into fibres, and then solidifying the fibres through a chemical process.

History of Lyocell Fabric

It was invented in the 1970s by the Austrian company Lenzing AG as an eco-friendly alternative to rayon. Commercial production of Lyocell fabric began in 1987, offering softness, breathability, and sustainability, making it a popular choice in the textile industry.

Characteristics of Lyocell Fabric

- It is renowned for its exceptional softness, breathability, lightweight and moisture-wicking properties.

- The resulting fabric is highly versatile and used in a variety of applications, including clothing, home textiles, and bedding, offering a sustainable and comfortable alternative to other fabrics.

Modal Fabric

Modal is another type of cellulose-based organic man-made fibre or regenerated fibre that is soft, breathable, and resistant to shrinkage. It was invented in the 1960s by the Austrian company Lenzing AG.

Characteristics of Modal Fabric

- It is renowned for its softness, smoothness, and excellent drape.

- Modal fabric is highly absorbent, breathable, and resistant to shrinking and fading.

- It provides comfort and versatility, making it ideal for various clothing applications such as underwear, loungewear, and activewear.

- Modal is known for its eco-friendly production process, as it requires less land and water compared to other fabrics. Its luxurious feel and sustainable qualities have made the modal fabric a popular choice in the fashion industry.

Man Made Synthetic Fibres

Man-made synthetic fibres are textile materials that are entirely synthetic and not derived from natural sources. These fibres are created through chemical synthesis by combining various chemicals and polymers to form long, continuous filaments. Synthetic fibres offer a range of properties, including high strength, durability, resistance to wrinkles, and the ability to retain their shape. Common examples of man-made synthetic fibres include polyester, nylon, acrylic, and spandex.

Polyester

Polyester is a synthetic man-made fibre made out of petroleum. This is one of the most popular man-made fabrics in the market.

The Evolution of Polyester

The polyester fabric was discovered by scientist W.H. Caruthers in the late 1930s. Later a group of British scientists applied Caruthers’s process in 1941 and discovered the first commercial polyester fibre called Terylene. DuPont purchased the legal rights in 1946 and created another polyester fabric called Dacron. In 1958, another polyester fabric, Kodel was discovered by Eastman Chemical. Today, polyester is known by some other names also like Polythylene terephthalate, PET, Microfiber etc.

Characteristics of Polyester

- Polyester fabric is a synthetic textile made from a polymer called polyethene terephthalate (PET). It is known for its exceptional durability, strength, and resistance to wrinkles, stretching, and shrinking.

- Polyester fabric is also lightweight, quick-drying, and resistant to mildew and abrasion.

- It has low absorbency, which means it does not retain much moisture. It dries quickly, making it suitable for activewear, swimwear, and outdoor clothing.

- This fabric is resistant to fading from exposure to sunlight and UV rays. It retains its color vibrancy even after prolonged sun exposure.

- It is commonly used in various applications, including clothing, home furnishings, upholstery, and industrial products. Additionally, polyester can be blended with other fibres to enhance its properties, such as moisture-wicking capabilities for sportswear or a softer feel when mixed with cotton.

Nylon

Nylon is a synthetic man-made fibre made from a polymer called polyamide. It was first developed in the 1930s by DuPont. It was a ground braking invention during that time and most of the parachutes in World War II were made using Nylon.

Characteristics of Nylon

- It is known for its exceptional strength, durability, and resistance to scraping.

- It is lightweight, quick-drying, and has good elasticity, making it popular for use in clothing, particularly activewear and swimwear.

- Nylon is also widely used in the production of stockings, parachutes, ropes, and industrial materials. It can be blended with other fibres to enhance its properties. Overall, nylon fabric offers versatility, performance, and long-lasting quality, making it a staple in the textile industry.

Acrylic

Acrylic is a synthetic fossil fuel-based fibre textile, a kind of synthetic wool which is made from polymer fibres called Acrylonite derived from petroleum.

Acrylic fabric can mimic the appearance and feel of natural fibres like wool while offering increased durability and ease of care. It is cheaper than wool as well. Whereas, it is highly flammable as opposed to natural wool.

Characteristics of Acrylic

- It is known for its softness, lightweight, great insulation just like wool and ability to retain color vibrancy.

- It is resistant to wrinkles, shrinking, and fading, making it a popular choice for winter clothing, blankets, upholstery, and outdoor textiles.

- Acrylic fabric is also resistant to moths, mildew, and sunlight damage.

- It is less breathable causing potential discomfort in hot weather. It is also prone to pilling and can have a static charge. Additionally, acrylic production involves the use of chemicals and petroleum, making it less environmentally friendly compared to natural fibre alternatives.

Spandex

Spandex is a synthetic fabric known for its elasticity. This is widely used to make activewear, swimwear, socks, innerwear etc. It is also called wonder fibre. Because it can be stretched four to six times its original size.

Evolution of Spandex

Spandex was developed in the late 1950s by chemists Joseph Shivers and C. L. Sandquist at the chemical company DuPont. The development of spandex was part of a larger research effort to create synthetic fibres with improved elasticity and stretch properties. The name “spandex” is an anagram of the term “expands,” which refers to the fabric’s ability to stretch. It was introduced as a brand name by DuPont, and it quickly became widely used to describe this type of synthetic elastomeric fibre. DuPont first showcased spandex to the public in 1959 under the brand name Lycra. Fibre gained popularity for its remarkable stretch and recovery properties, and it revolutionized the textile industry by providing a new level of comfort and flexibility in clothing.

Characteristics of Spandex

- Spandex is highly elastic and can stretch up to 500% or more of its original length without losing its shape. This exceptional stretch and recovery make it ideal for body-hugging garments that require flexibility and comfort making it a popular choice for undergarments, activewear, loungewear, shapewear etc.

- This fabric is extremely durable, and lightweight, making it comfortable during physical activities.

- Though made from synthetic fibre, it can be blended with other fibres like cotton, and rayon to enhance their stretch properties. These blends offer a balance of stretch, durability, and comfort, depending on the desired application.

- Spandex is sensitive to heat and is known for poor breathability. It does not allow air to pass through easily, which can lead to a lack of ventilation and potential discomfort, especially in hot and humid conditions.

- This is prone to pilling/bubbling. Sometimes this can cause allergic tendencies depending on the skin type.

Other Man-Made Fabrics

Fibreglass

It is made from fine fibres of glass that are spun into threads. It is known for its strength, durability, and resistance to heat, making it suitable for applications such as the insulation industry, reinforcement in composites, and construction materials.

Carbon Fiber

Carbon fibres are composed of carbon atoms bonded together in a crystal-like structure. They offer exceptional strength, stiffness, and lightweight properties, making them ideal for high-performance applications like aerospace parts, automotive, golf club shafts and other sports equipment, and sailboat masts.

Aramid

Aramid fibres, such as Kevlar and Nomex, are heat-resistant and have high tensile strength. They are widely used in protective gear, bulletproof vests, and aerospace applications, in bicycle tires, marine cordage, marine hull reinforcement etc.

Ceramic Fiber

Ceramic fibres are made from inorganic materials like alumina and silica. They are known for their high-temperature resistance and are used in applications such as insulation, fireproofing, and filtration.

Asbestos

Asbestos is a kind of synthetic fabric asbestos fibres. In the past, asbestos was woven into fabric or used as insulation material due to its heat resistance and durability. However, they pose severe health risks when inhaled, as they can cause lung diseases, including mesothelioma and lung cancer. Asbestos is now strictly regulated or banned in many countries due to its harmful effects.

Conclusion

In conclusion, man-made fibres have undoubtedly revolutionized the textile industry, offering a vast array of possibilities and benefits. From the durability of polyester to the softness of viscose rayon and the stretch of spandex, these synthetic fibres have transformed the way we produce and wear fabrics. Their versatility, performance, and ability to mimic natural materials have propelled the industry forward, ushering in a new era of creativity and functionality in fashion and textiles. Moreover, the use of man-made fibres has reduced dependence on natural resources and provided alternatives to materials like fur and leather, promoting more ethical and sustainable fashion choices. Again we have to remember all these fabrics are not sustainable for us and our nature. The production and disposal of man-made fibres have environmental implications, emphasizing the need for responsible manufacturing processes and recycling initiatives. It is our duty to carefully choose fabrics for our needs.

If you want to learn What is fibre? What different types of fibres exist and how different types of fibres are obtained to make fabric then click the below button.

Click the button below to explore various types of fabrics derived from animal-based protein fibres. Discover their properties, uses, and historical significance.

Click the button below to explore various types of fabrics derived from plant-based or cellulosic fibres. Discover their properties, uses, and historical significance.

Whether working on a sewing project, managing a manufacturing company, or simply purchasing fabric for yourself or a loved one, choosing the appropriate fabric for garments is of utmost importance. Read the below article to understand 9 must-know factors you need to know while selecting fabric for garments.